A55 Warren Bank Interchange Improvement |

78.2% |

Whole Project Award

Project Team

Client: Flintshire

County Council and Welsh

Government

Design: Atkins

Construction: Alun

Griffiths (Contractors) Ltd

The Project

The project provides improvements to the junction of the A55(T)

trunk road and the A5104, located to the west of Broughton

in Flintshire, North Wales. Prior to the works, the interchange

allowed only limited movements and comprised a bridge carrying

the A5104 over the A55(T) – the primary trunk road serving

towns along the North Wales coast – with T-junctions

on the A5104 linking to the on-A55 slip heading west and the

A55 off-slip from the west.

Traffic travelling westbound on the A55(T), or wishing to leave the A5104 eastbound onto the A55(T), had to travel through Broughton to access or egress the A55(T) at the next interchange. In addition there were no footpaths or cycleways linking to the A5104 bridge crossing.

Figure 1 – Completed project looking east showing the new slip roads and eastern roundabout on the A5104, the retained vegetation and revised roadway on the bridge with new cycleway and footpath

Expansion of the nearby Airbus factory, Broughton Retail Park and other developments in the local area has resulted in an increased demand on the local county highway network. The planning consent for the proposed business park development at Warren Hall recognised this and included a condition to improve the interchange. The improvement encompassed the construction of two new east facing slip roads and roundabouts on the A5104 to connect with the slip roads. This will provide network benefits by reducing traffic flows through Broughton village. The carriageway over the bridge was reduced in width to allow incorporation of segregated foot and cycleways. The improvement will also provide significant environmental and highway safety improvements to local communities.

CEEQUAL was applied from the outset of the project, with

an aspiration to achieve the highest score possible. The project

sought to minimise the impacts of the works to the environment,

adjacent properties, and road users; as well as maximising

reuse of the existing highways (94% were retained) and keeping

any additional land take beyond the original highway edge

to a minimum. Good traffic management and scheduling of works

ensured that the A55(T) was kept open for the duration of

the 14 month construction programme, and the A5104 was closed

for just 4 days to allow the final ‘tie in works’.

Project challenges and solutions

The small size of the site, and surrounding sensitive receptors, provided particular challenges in terms of minimising impacts whilst maximising opportunities for environmental improvements. The project comprised just 6.6ha, of which 18% was already occupied by the existing highways. A small stream along the northwest boundary, and housing estate adjacent to the new eastbound-on slip provided further constraints to design and construction.

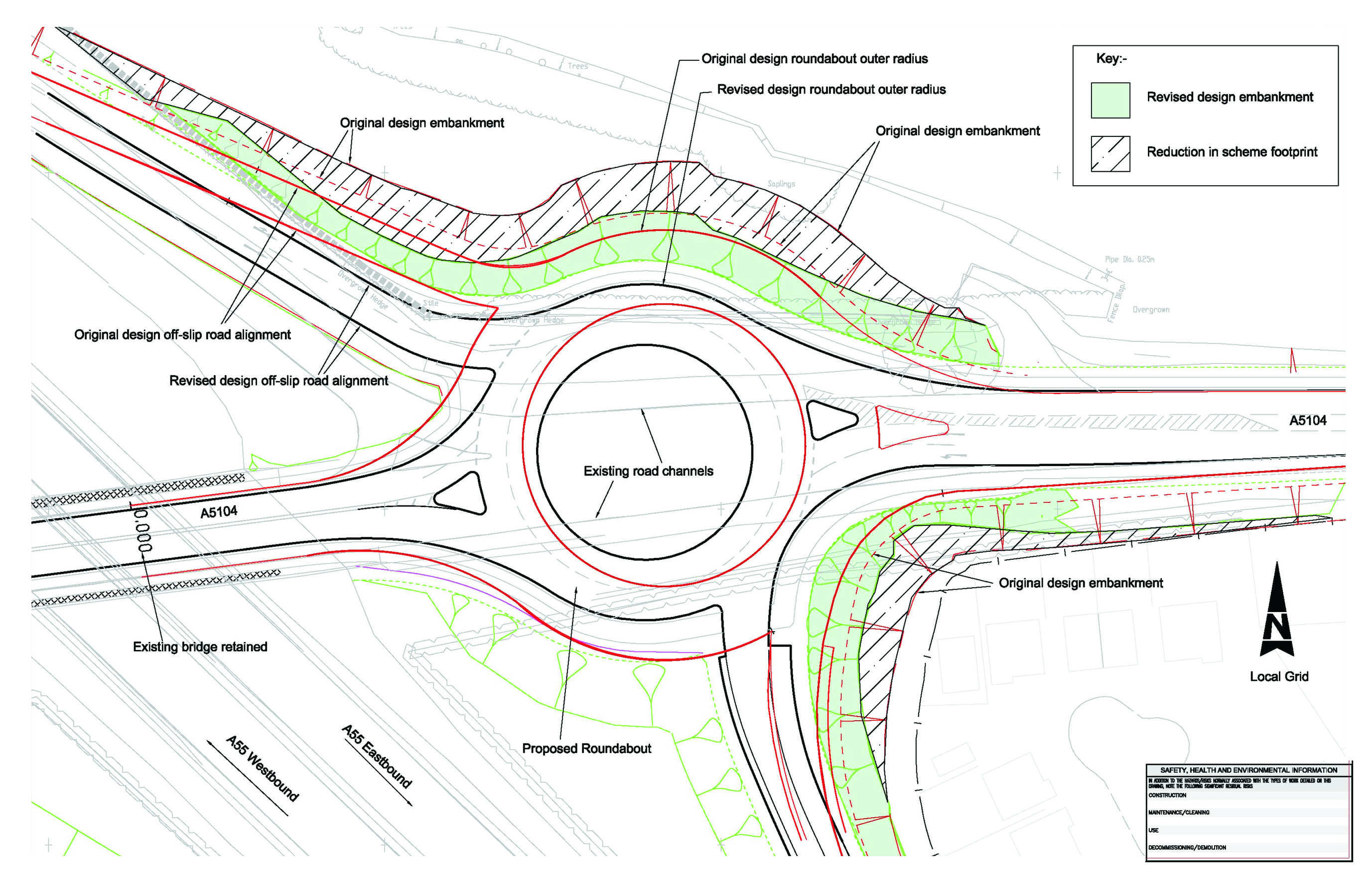

Figure 2 shows the re-design of the eastern roundabout to reduce its landtake. The red lines show the original design alignment, with the black lines the revised design (and constructed) alignment.

Figure 2 - Redesign of eastern roundabout

to reduce landtake

Minimising impacts during construction

Key construction impacts to people were noise and vibration from plant and works, disruption caused by construction vehicles and the works themselves. Impacts from plant and works were minimised through consideration of the location of plant and the scheduling of activities. An acoustic screen and cut-off trench were constructed between the adjacent houses and slip road to reduce noise and ground borne vibration effects.

The design of the project sought to reduce requirements for imported materials, thereby reducing numbers of construction vehicles. For example, the use of vibro stone columns under the roundabouts and northern sections of the new slip roads avoided the need to excavate (and export from site) the weak in-situ materials and replace them with imported fill, as would have been required if a conventional design was employed. The required imported fill was sourced from local recycled sources, with haulage routes selected to avoid local villages. All material excavated on site was re-used within the site, primarily for the construction of landscape mounds designed to soften the appearance of the slip road embankments, thereby avoiding the need for disposal off-site and further construction traffic.

Scope for ecological enhancements was limited as the site lies under the approach to Hawarden Airport and encouraging bats and birds was considered undesirable. Ecological enhancements took the form of diverse planting and the construction of habitat piles in adjacent woodland.

Whilst some clearance of existing vegetation was required, 94% of mature trees and 50% of the hedgerows present were retained, and protected during the works. Cleared vegetation was taken by Chester Zoo for the animals.

Minimising impacts during operation

Surface water drainage was designed so as to limit impacts of flooding and spillages. The drainage ties into existing highway drainage system, but with attenuation so that discharges to the downstream surface water storage lagoon are the same as for the original interchange layout.

Lighting was designed to avoid light spill onto neighbouring receptors, and also to have a low energy demand with the option to dim the lights when required.